EXTENSIVE PRODUCT RANGE FOR A WIDE VARIETY OF APPLICATIONS

We have been producing process chemistry for metal surface finishing for more than 100 years. What began in 1905 with black oxidising salt today encompasses a wide range of products for all chemical metal finishing requirements. Here we inform you about our product range and the application processes for the chemical treatment of metal.

OUR PRODUCT RANGE

DEWE Brünofix Alkalit products

- Depending on the application

- From gentle cleaning agents to highly alkaline concentrated degreasing agent

- Easy handling

- Preparation and supplement possible with just one product

- Flexible

- Hot and cold processes, powder or liquid form

- Dependent on the product, derusting and activating at higher concentrations

- Demulsifying

- Suitable for use with ultrasound

- Also suitable for non-ferrous metals

DEWE Brünofix Rostalit products

- Based on hydrochloric acid, sulphuric acid, phosphoric acid and mixed pickling fluids

- Complete pickling agents, i.e. the products already contain surfactants and inhibitors

Note: Inhibitors can also be purchased separately.

DEWE Brünofix Brün products

- For 1, 2 or 3 bath treatment methods

- All black oxidation salts contain a highly-active long-term spray protection

- Universal product for a broad application

- Special products for special applications:

- Hardened and high-alloy steels

- Products for the weapons industry

- Cast materials

- Stainless steels

DEWE Brünofix Phosphata products

- Zinc, manganese and zinc calcium phosphating agents for use in immersion processes

- Layer thickness can be specifically controlled by adding our special accelerating solution to the phosphating bath for zinc and zinc calcium phosphating agents

- Pre-activation agents for zinc, zinc calcium and manganese phosphating agents to influence layer strength and layer structure

DEWE Brünofix cold colouration products

Cold black oxidation

- Black colouration for cast and iron materials

- Application at ambient temperature

- Low plant engineering outlay

DEWE Brünofix Mekupa products

Colouration of brass and copper

- Brown or black colouration

- Cold or hot processes

DEWE Brünofix Zanova products

Blackening of die-cast zinc

DEWE Brünofix Neusilber products

Black and brown colouration of nickel silver

DEWE Brünofix Emulsin products

Emulsions

- Matt to slightly shiny surfaces, dependent on the product

- Good corrosion protection

- Variable oil film, dependent on the mixing ratio

- 5–20 vol-% preparation

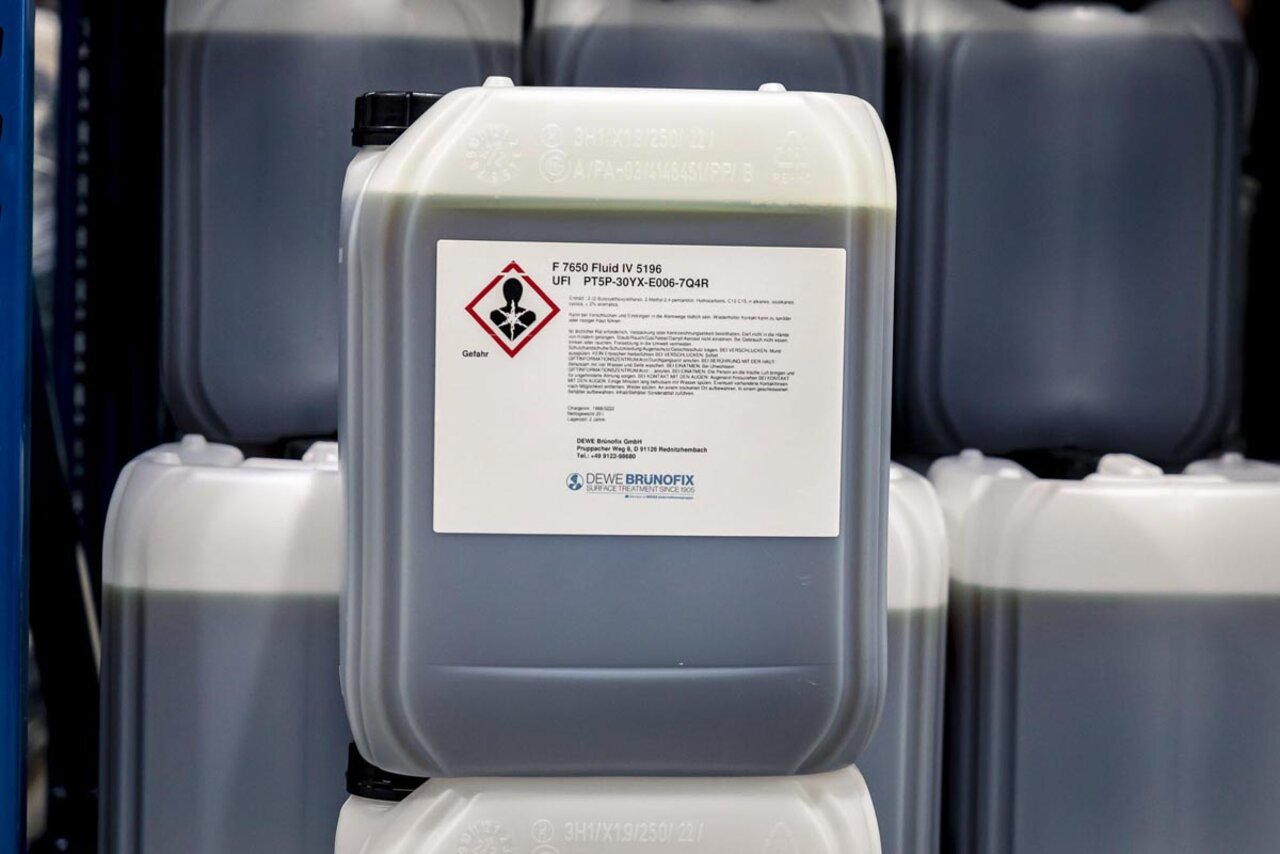

DEWE Brünofix Fluid products

Dewatering agents

- Matt surfaces that can be painted or oily, shiny surfaces, dependent on the product

- Washable, ensuring a very long lifetime

- Usually without fire hazard categories

- Ready-to-use product

DEWE Brünofix Passivation products

Passivation

- For temporary corrosion protection for indoor storage

- Water-soluble corrosion protection concentrate

- Can normally be painted over

- Low batch pH: 1 -3 vol-%

DEWE Brünofix Korrosin products

Boiling oil

- Particularly suitable for black oxidised surfaces with blind holes, etc. as any black oxidation salt residues will be subject to saponification

- Good long-term corrosion protection

APPLICATION PROCESS

BLACK OXIDATION

A black oxidation layer is chemically generated by immersing workpieces in a boiling, strongly alkaline solution. This creates an oxide layer on iron and steel materials (magnetite – Fe3O4).

PHOSPHATING

The aim is to build up a fine-grained phosphate layer and to avoid creating phosphate layers with large grains.

COLOURING

Classic black oxidation products, as used for steel or iron materials, cannot be used to colour stainless steel materials.

DEGREASING

The prerequisite for producing a chemical metal colouring is providing a metallically clean surface. Mechanically adhering greases and oils, dust and processing residues are removed by immersing the workpieces in a degreasing bath.

PICKLING

The pickling process can influence the surface activity very positively, even for hardened workpieces.

POST TREATMENT

The corrosion protection of a chemically produced surface layer is determined by the choice of post-treatment product.